DESIGN OFFICE

Engineering and design

ArcInnov Technologies provides innovative technical solutions for all players in the steel industry, covering a wide range of areas of expertise, from scrap transport and steel melting via its emblematic electric arc furnace, to the transport of liquid steel through to solidification and finishing.

Our design office, based at the historic Creusot Loire site in the Novaciéries sector of Saint-Chamond (Loire (42) – France), has since its creation combined its design and project management skills with those of its local and regional partners, as well as its proximity to its customers, to perfect its offer and become a French steel equipment manufacturer.

To complement our design and technical assistance activities, we have forged close links in recent years with specialists in hydraulic fluids, pneumatics, electricians/automation engineers, metallurgical process specialists and boilermakers to build our equipment. Our close working relationship with these specialists means that we have full control over all post-design operations, and contribute to quality control at the end of the production process.

Since 2012, our young company, thanks to its own experience and the extensive technical support of its experts in various fields, has been offering its customers a wide range of services, combining technical expertise with the two major advantages of a human-scale structure: ease of contact and responsiveness.

Our experience and resources enable us to offer a wide range of services.

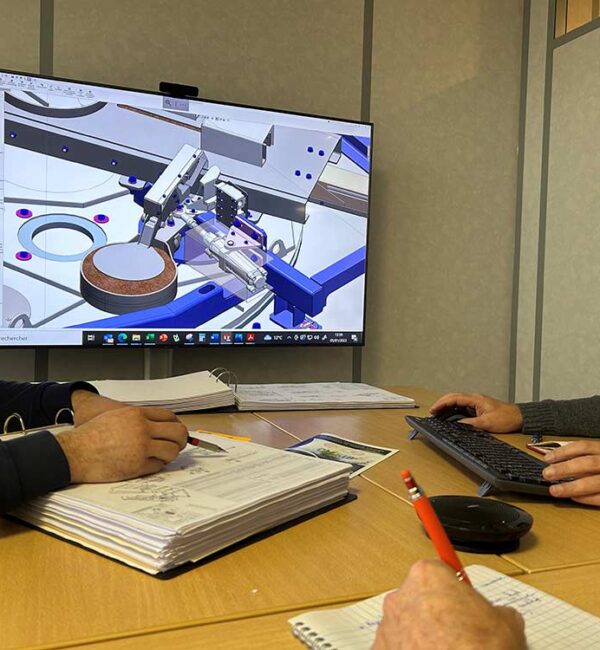

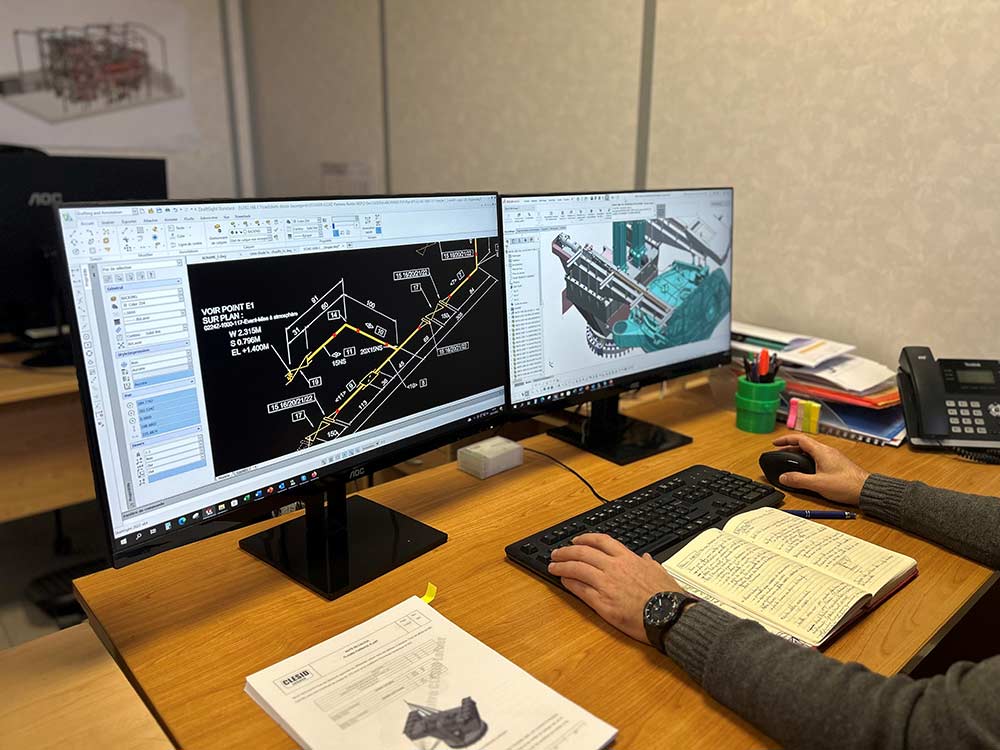

THE 3D

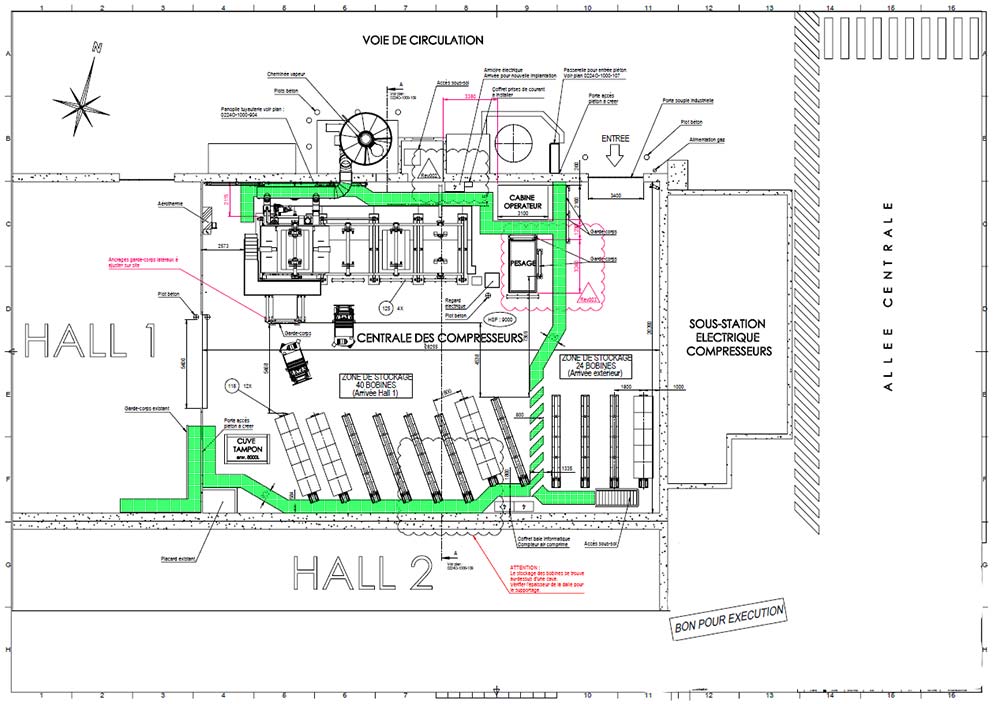

General layout studies

Our 3D modeling resources enable us to offer our customers general equipment integration/layout studies. Through this service, we integrate the desired equipment and networks into a predefined, constrained environment, and use our expertise to suggest the best solution, taking into account all related constraints and requirements, and draw up a budget.a

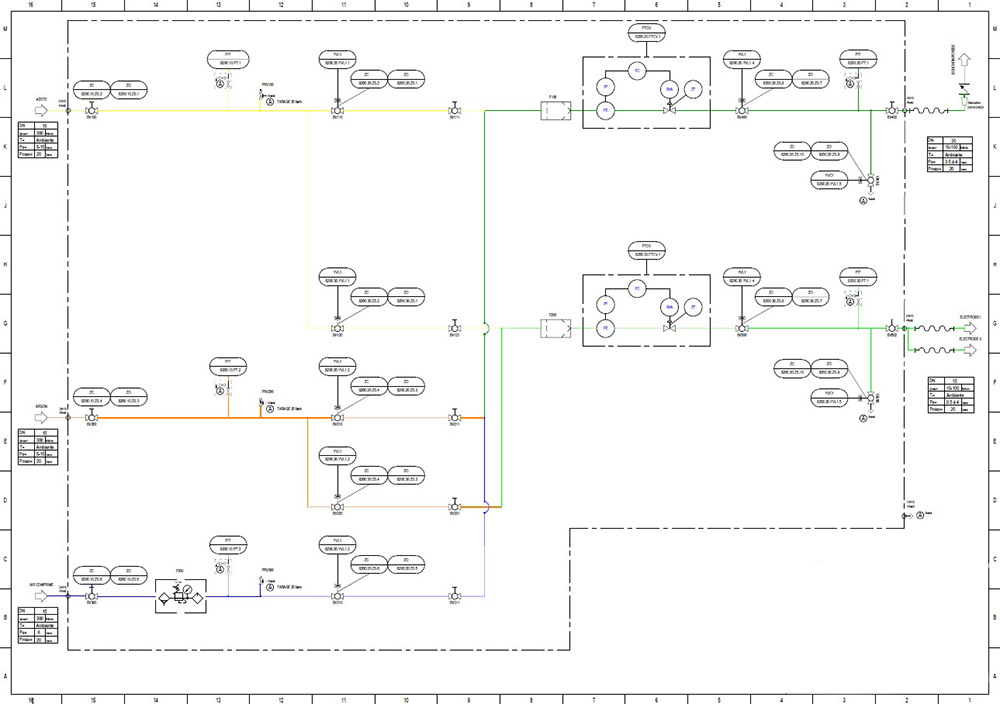

Overall drawings, civil engineering guide drawings, load descriptions, P&ID process (Piping and Instrumentation Diagram), fluids, 3D renderings and videos, and much more can be provided.

OPTIMUM TECHNICAL SOLUTIONS

Equipment design studies

TWO DIRECTIONS

Process studies

- Utility sizing: We use in-house calculation models to characterize fluid networks of various kinds (industrial water, nitrogen, argon, compressed air, O2). We determine the intrinsic characteristics of the fluid (flow rate, pressure, velocity, pressure drops, etc.) and, in the case of an existing network, we check its potential for development in the context of a process modification, or we determine the geometric characteristics of a future installation.

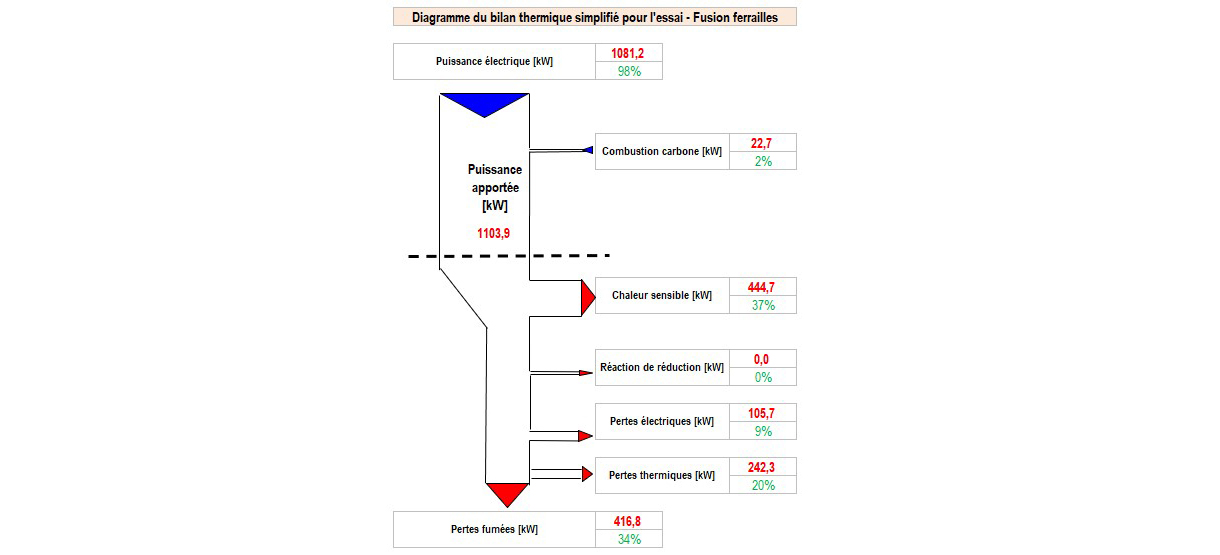

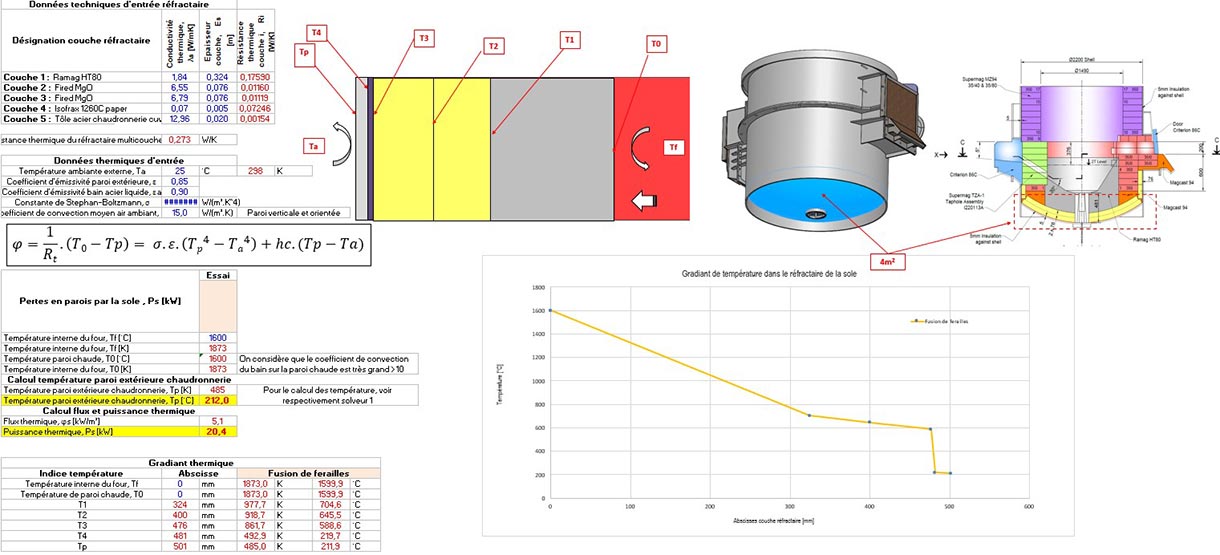

- Heat balance: Often necessary in the pre-study phase, the heat balance of a piece of equipment enables us to determine the average power required to implement a process. ArcInnov Technologies, as a manufacturer of steelmaking equipment, mainly arc furnaces, has calculation models for this type of equipment among others. A heat balance in its complete model breaks down into 3 stages.

- Material balance: study of chemical reactions during the melting phase

- Heat loss balance: calculation of thermal gradient, wall losses by radiation, conduction and convection

- Additional losses: cooling losses, electrical losses (Joule effect)…